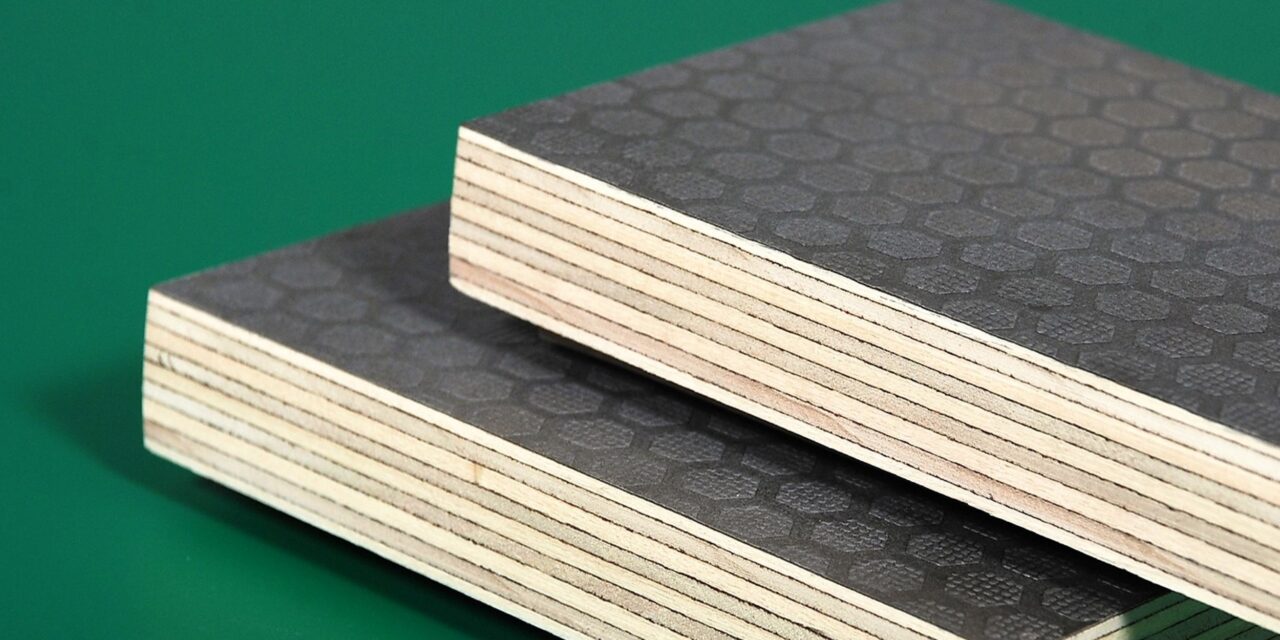

Panel

The plywood panels are glued crosswise with a water-resistant phenolic resin. The gluing meets the requirements of EN 314-2 class 3 – the highest gluing class for plywood in outdoor use.

Surface

The plywood panels are calibrated and have a repaired surface. Mistakes are repaired with putty.

The edges are not sealed.

Application

The plywood panels are particularly suitable for further surface processing in the furniture, construction or automotive sectors. Due to the sealed, calibrated surface and the waterproof gluing, the panels are also suitable for outdoor use.

Plywood thickness

| Thickness in mm | Number of veneers | Weight in kg/m2 | Weight/pack in kg | Number of sheets /pack |

|---|---|---|---|---|

| 10 | 5 | 4,80 | 1520 | 101 |

| 12 | 5 | 5,76 | 1520 | 84 |

| 15 | 7 | 6,72 | 1520 | 72 |

| 18 | 9 | 8,32 | 1520 | 56 |

| 21 | 9 | 9,92 | 1520 | 48 |

| 24 | 11 | 11,20 | 1520 | 42 |

| 27 | 13 | 13,12 | 1520 | 36 |

| 30 | 13 | 14,08 | 1520 | 34 |

Other thicknesses on request

Plywood dimensions

1250 x 2500 mm/ 2500 x 1250 mm (only on request)

Tolerance length/width: according to EN 315

Wood moisture 10% +/- 2%

Structural properties

| Thickness in mm (EN 315) |

E-Modul in N/mm2 (EN 310) |

Bending strength in N/mm2 (EN 310) |

||

|---|---|---|---|---|

| Em5%II | Em5%┴ | fm5%II | fm5%┴ | |

| 15 | 3330 | 2766 | 32 | 28,5 |

| 18 | 3330 | 1946 | 31 | 29,7 |

| 21 | 4197 | 1943 | 31,3 | 23,3 |

Other panel thicknesses on request

FSC® or PEFC® compliant delivery is possible on request